1 8 Sheet Metal Bend Radius

In other words if you re bending 1 8 sheet use a tool with a 1 8 radius to form the inside of the bend.

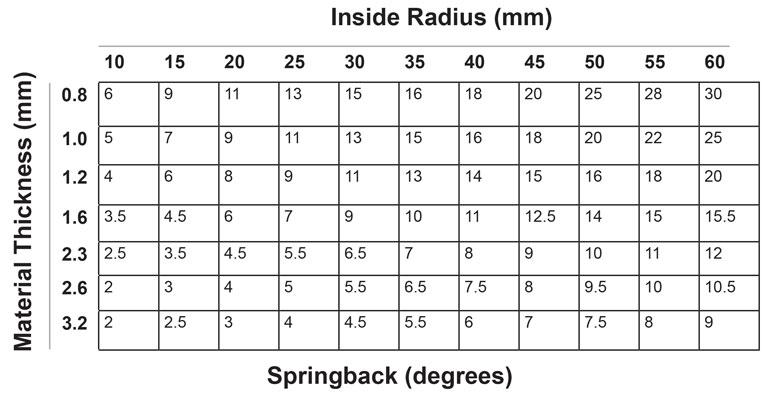

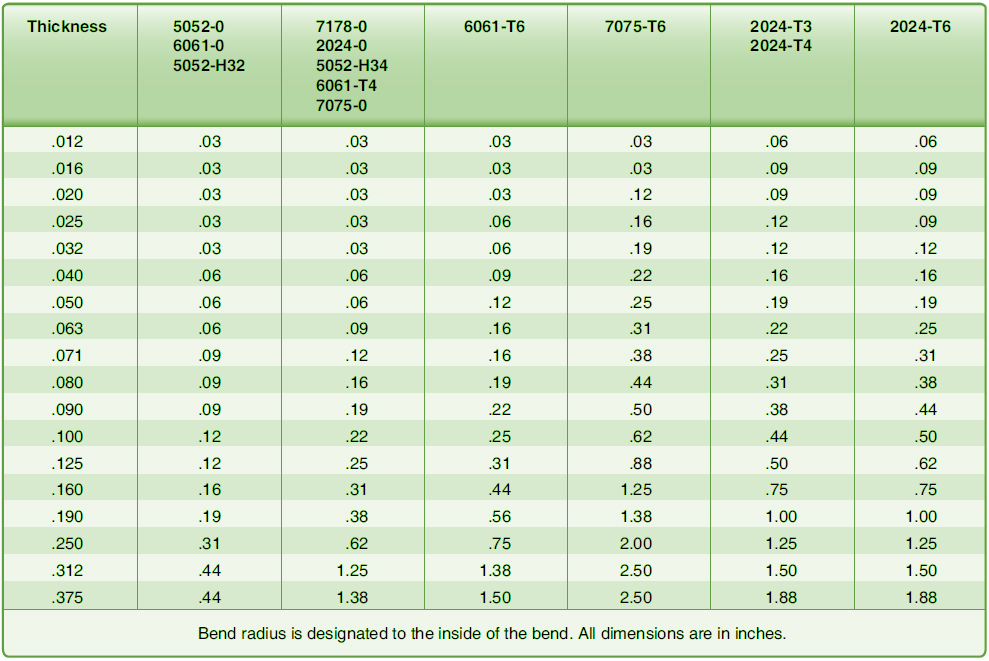

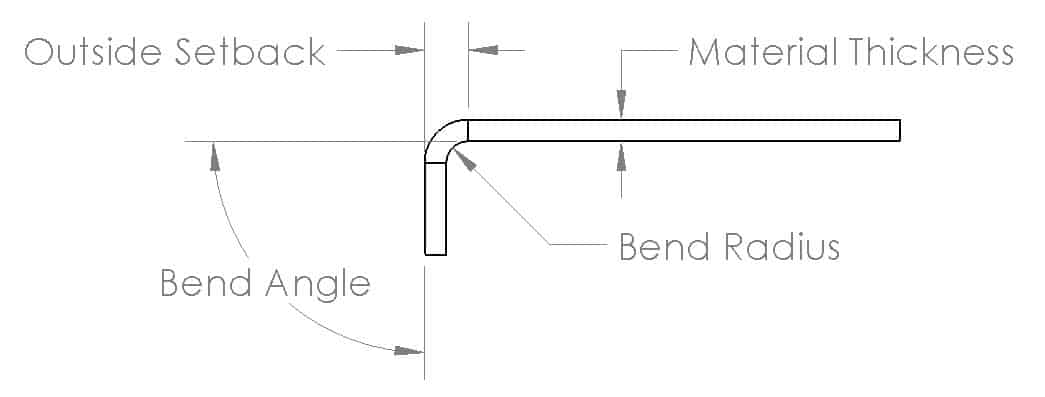

1 8 sheet metal bend radius. The bend radii listed are standard minimum if manufacturing for aircraft and aerospace applications. When the sheet metal is put through the process of bending the metal around the bend is deformed and stretched. Here s a good rule of thumb for most materials. Radii for various thicknesses expressed in terms of thickness t.

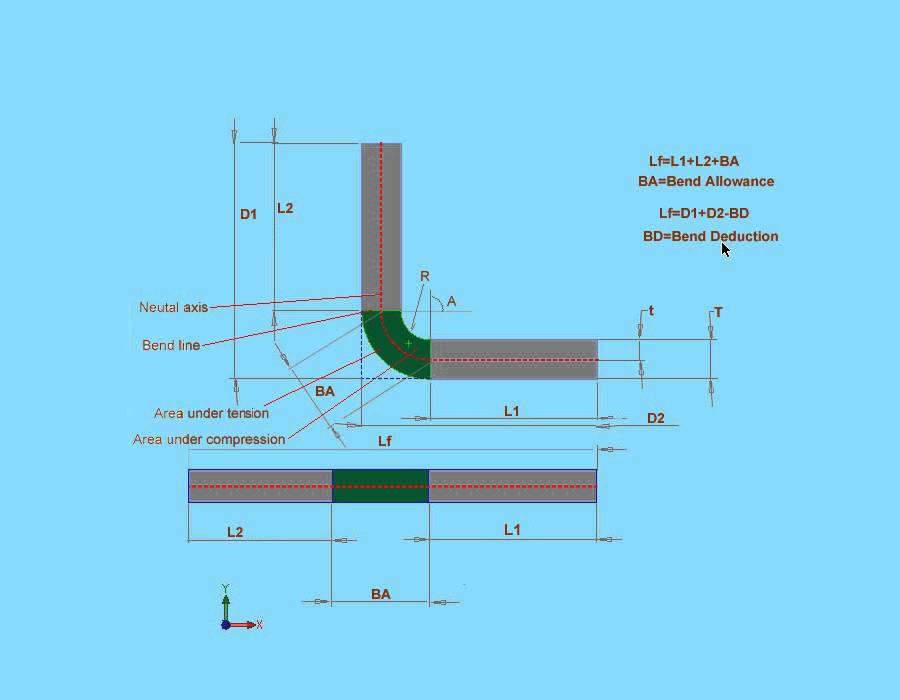

Since commercial sheet metal bending can be done with less concern for stresses caused during forming operation the radius can be near zero for thin sheet metal. I can now see that the minimum flange length is 8 5 mm for such a bend so i have to keep it in mind when designing. Thickness minimum bend bend radius. Bend allowance mild sheet steel 90 degree bend allowance bend allowance chart example flat size 2 2 095 3 905.

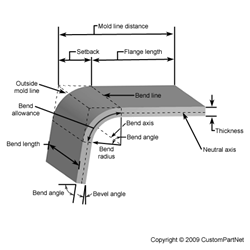

Thick grade 350 and 400 may have a minimum bend radius of 2 5 times the material thickness when transverse bending while longitudinal bending may require a minimum bend radius that s 3 75 times the material thickness see figure 1. Or 1 866 849 3911 and we can help. To keep it simple i also use a 2 mm inside radius. Understanding the bend allowance and consequently the bend deduction of a part is a crucial first step to understanding how sheet metal parts are fabricated.

We go beyond the general rules of sheet metal bending as our customers want. Per the aluminum association inc. You will need to know your material thickness mt the bend angle b the inside radius ir and the k factor k. Let s say i have a 2 mm thick sheet and i want to bend it.

As this happens you gain a small amount of total length in your part. Aluminum minimum bend radii for 90 degree cold forming of sheet and plate. The minimum bend radius data shown in these charts is measured to the inside of the bend. The tables below show bend radii and minimum bend sizes for materials and tooling combinations stocked by protocase.

The material thickness will be measured in decimal form not by the gauge number. The bend allowance formula takes into account the geometries of bending and the properties of your metal to determine the bend allowance. If you re bending 0 020 thick material use a 0 020 radius. The inside bend radius should be equal to the thickness of the material that you re forming.

In steel between 0 5 and 0 8 in. 0 060 crs 2 000 2 000 r0 031 aluminum 90 deg.